Optical Fabrication

Optical Fabrication

Let's Discuss Your Project NeedsOpticology takes pride in its custom-focused approach, offering a wide spectrum of optical components spanning from precision to commercial quality. Our commitment to serving both the Research & Development (R&D) and Original Equipment Manufacturer (OEM) markets, coupled with our unique in-house engineering expertise, sets us apart as an industry leader in optical fabrication.

The Advantage of In-House Engineering:

At Opticology, we empower our customers by having in-house engineering expertise readily available. This distinct advantage allows us to address challenges and provide tailored solutions on the spot, ensuring that your optical fabrication needs are met with precision and efficiency.

Diverse Range of Components:

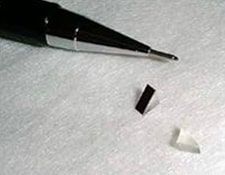

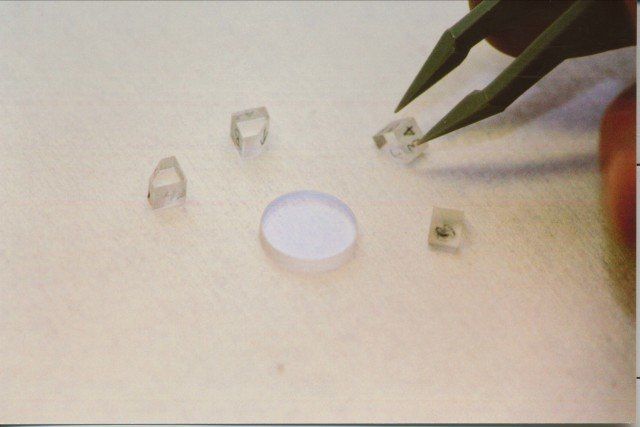

Over the years, we have manufactured an extensive array of optical components, including lenses, mirrors, prisms, filters, and more. These components have found applications in a multitude of cutting-edge systems, such as LIDAR, whispering gallery mode resonators, surface plasmon spectroscopy, ophthalmic instruments, fluorescence spectrometers, colorimeters, optical transceivers, fiber coupling systems, laser ablation systems, and beyond.

Unlocking Optical Fabrication Excellence with Opticology:

Custom-Centric Approach: Our commitment to custom solutions ensures that your unique requirements are met with precision and attention to detail.

Broad Industry Application: Our components serve diverse industries, from cutting-edge research to advanced technologies, offering versatility and adaptability.

In-House Expertise: Opticology's in-house engineering expertise positions us as a trusted partner for addressing challenges and delivering tailored solutions.

Quality Assurance: We uphold the highest standards of quality in optical fabrication, ensuring that our components meet or exceed industry expectations.

Experience the pinnacle of optical fabrication excellence with Opticology. Explore our comprehensive range of optical components and discover how our expertise can elevate your projects and applications. Trust in our commitment to precision and innovation as we transform your optical visions into reality.

The Advantage of In-House Engineering:

At Opticology, we empower our customers by having in-house engineering expertise readily available. This distinct advantage allows us to address challenges and provide tailored solutions on the spot, ensuring that your optical fabrication needs are met with precision and efficiency.

Diverse Range of Components:

Over the years, we have manufactured an extensive array of optical components, including lenses, mirrors, prisms, filters, and more. These components have found applications in a multitude of cutting-edge systems, such as LIDAR, whispering gallery mode resonators, surface plasmon spectroscopy, ophthalmic instruments, fluorescence spectrometers, colorimeters, optical transceivers, fiber coupling systems, laser ablation systems, and beyond.

Unlocking Optical Fabrication Excellence with Opticology:

Custom-Centric Approach: Our commitment to custom solutions ensures that your unique requirements are met with precision and attention to detail.

Broad Industry Application: Our components serve diverse industries, from cutting-edge research to advanced technologies, offering versatility and adaptability.

In-House Expertise: Opticology's in-house engineering expertise positions us as a trusted partner for addressing challenges and delivering tailored solutions.

Quality Assurance: We uphold the highest standards of quality in optical fabrication, ensuring that our components meet or exceed industry expectations.

Experience the pinnacle of optical fabrication excellence with Opticology. Explore our comprehensive range of optical components and discover how our expertise can elevate your projects and applications. Trust in our commitment to precision and innovation as we transform your optical visions into reality.

Contact Us With Your System Or Component Requirements To Learn More About How Opticology Can Help

Conventional Optics

We have fabricated many of the optics we have designed which is advantageous to our customers typically saving costs as we both design and build. Custom single element lenses, doublets, and prisms all can be produced economically especially when quantities scale up for production. Opticology is very price competitive on production optics with the added benefit of in-house engineering to work through efficient production implementation.

Critical Assemblies

Opticology, Inc. routinely designs and builds critical precision optical and opto-mechanical assemblies for its clients. These assemblies are a collection of components that require a high degree of skill and expertise to produce, and generally form the hardware basis of a research, prototype, or production instrument.

With Opticology's broad capabilities, industry contacts, and internal skilled labor we are able to provide complex components, sub-systems, and systems within a reasonable time frame and cost. Many of the optical subassemblies & assemblies we have built have come from customers without a design on paper but with an idea or sketch of what is needed to make their project move forward.

Material Processing

Core Drilling

Usually Requiring A Multi-Step Process In Fabrication,Opticology's Role Has Been To:

1. Inform the customer of technical feasibility with regard to both their goals and their resources

2. Propose alternative or more suited specifications (cost/manufacturability)

3. Develop viable, multiple-step fabrication processes

4. Work with customers designs to produce drawings and specify tolerances

5. And finally build, assemble, and ship the parts

Please Feel Free To Email Us With Your Requests For Quotations Or Inquires.

Submit your request and we'll get back to you soon.

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later

For over 20 years, Opticology has successfully served customers in optical design, engineering, and fabrication.

Find Us

Opticology, Inc. 99 Commerce Street, Brooklyn, NY 11231

Contact Us

212-243-4328

info@opticology.com

© 2024

All Rights Reserved | Opticology Inc.